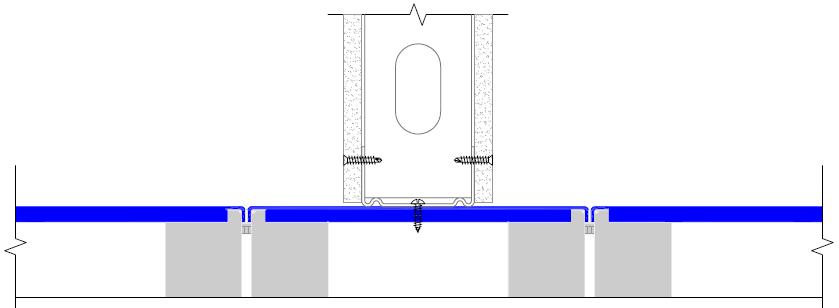

Grand Square Series

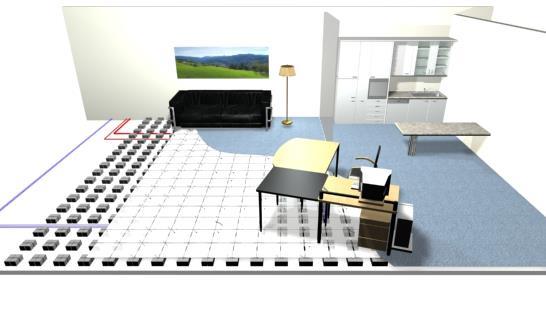

Since the advent of the Internet and intranet, the raised access floor industry has experienced rapid growth. In addition to traditional markets such as data centers and factories, access floors are now extensively used in nearly all new construction and retrofit projects for class-A office buildings, that support the government, commercial and educational sectors. The raised floor systems of choice include both traditional access floors and newer low profile cable management access floors. There are also newly emerging markets for special application access floor systems in retail stores, showrooms, and temporary booths for shopping malls and trade shows. Netfloor’s Grand Square low profile access floor system has been designed especially for these new market segments. The system is very easy to assemble. Netfloor is also introducing the system for home improvement applications, to support creating a new room or living space in the basement or the garage of a house, where the sub-floors’ condition is often below-grade.